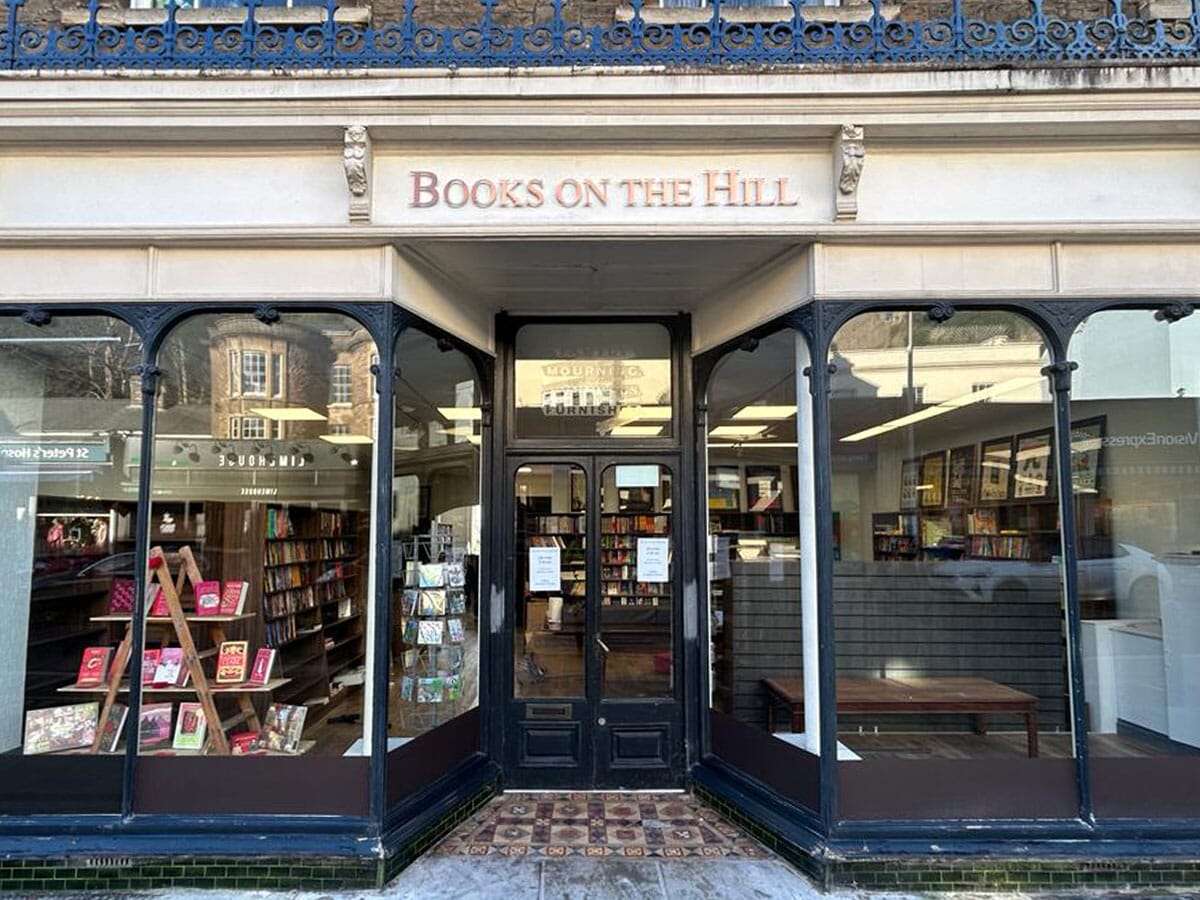

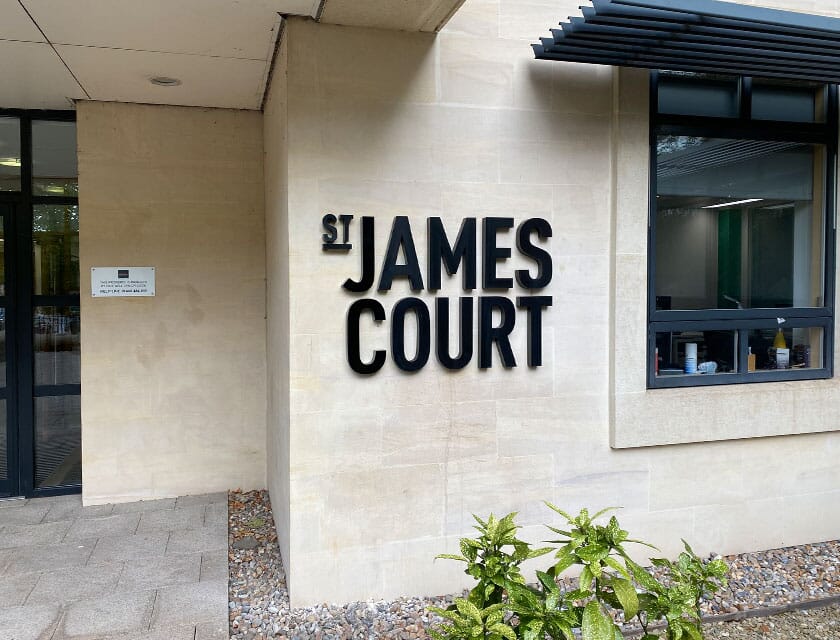

Shop Front Sign Designs & Ideas

Shop Front Signs

Looking for a new shop sign or shopfront signage ideas? Look no further than shop front signs!

We have a team of experienced professionals ready to help you choose the perfect shop sign for your business. We've worked with start up companies to large international organisations with national re-branding roll outs.

If you need assistance and are looking for a shop sign maker who uses high quality materials, we hope the shop front sign guides below help you.

How much does a shop front sign cost?

How much do storefront signs cost?

Shop front signs usually cost in the range of £450 – £2000 depending on size and whether you’re installing the shop sign or we are.

This price guide covers a variety of shop front sign designs and styles as well as some bespoke outdoor signs, of which there are many. On this page we’ve provided more detailed information and price ranges for each style of shop sign, business front door signs, outdoor signage, shop window graphics for your premises. If you’re looking for exterior building signs cost, they’re around the same prices as displayed here. Pavement signs and shop window graphics are on our dedicated pages.

This list is of course by no means complete and there are of course many other types of store front signs which we manufacture but it should hopefully serve as a good starting point when looking for a sign company.

If you’re looking for a bespoke sign maker, it might be of use to know that we make our own signs so can accommodate bespoke outdoor signs as well.

We’d love to hear from you

If you’re looking to get started with a new project, or you want to discuss some options, get in touch with our friendly team:

Shop Front Enquiry Form

Why choose Signet Signs?

We are a family run signage company, established in 1971, and are proud of our long standing reputation for exceptional customer service.

Whatever your signage projects requirements, we promise to provide a transparent experience and to keep you fully informed every step of the way.

Family run business

We specialise in the design, manufacture & installation of signs.Exceptional reputation

Check out our 150+ 5 star Google ReviewsHighly experienced

Established in 1971, we’re extremely experiencedSuperbly equipped facilities

We use the latest machines & technologies, all in houseLooking for inspiration?

Why not check out some examples of our previous work and other external signs?